Scaffold safety starts with structural integrity, and structural integrity begins with precise alignment. No matter how advanced or simple a scaffolding system might be, it’s only as stable as the fittings that hold it together. At the heart of this alignment lies a humble but indispensable component—the double coupler.

When it comes to the construction industry in regions like Saudi Arabia, where extreme temperatures and demanding load conditions are part of the daily environment, relying on high-quality couplers is not just an option—it’s essential. The double coupler in Saudi Arabia is widely recognized for its reliability in locking scaffold tubes together at a fixed 90-degree angle, ensuring vertical and horizontal elements remain exact in their alignment.

Let’s unpack why this specific component stands as a pillar of precision, safety, and dependability in scaffolding applications worldwide.

The Role of Precision in Scaffold Alignment

Precision in scaffolding isn’t a luxury—it’s a lifeline. A scaffold that’s slightly off-alignment can put excessive stress on load-bearing points, reduce stability under weight, and compromise worker safety. Misalignments—however small—can propagate errors across the entire scaffold structure. These faults are especially dangerous when scaffolds rise multiple stories, or when the work demands heavy-duty platforms for brickwork, concrete pouring, or façade installation.

Double couplers offer a solution engineered for exactness. By rigidly connecting two scaffold tubes at a fixed right angle, they prevent shifting and unwanted movement. This consistency allows engineers, foremen, and safety officers to plan, construct, and certify scaffold structures with full confidence in their integrity.

What is a Double Coupler?

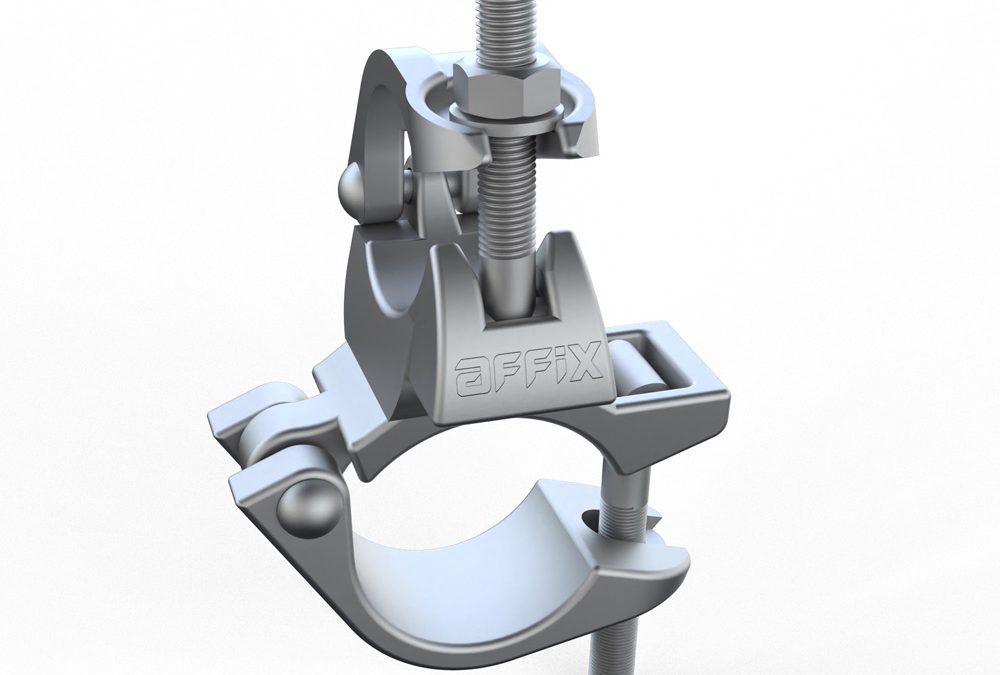

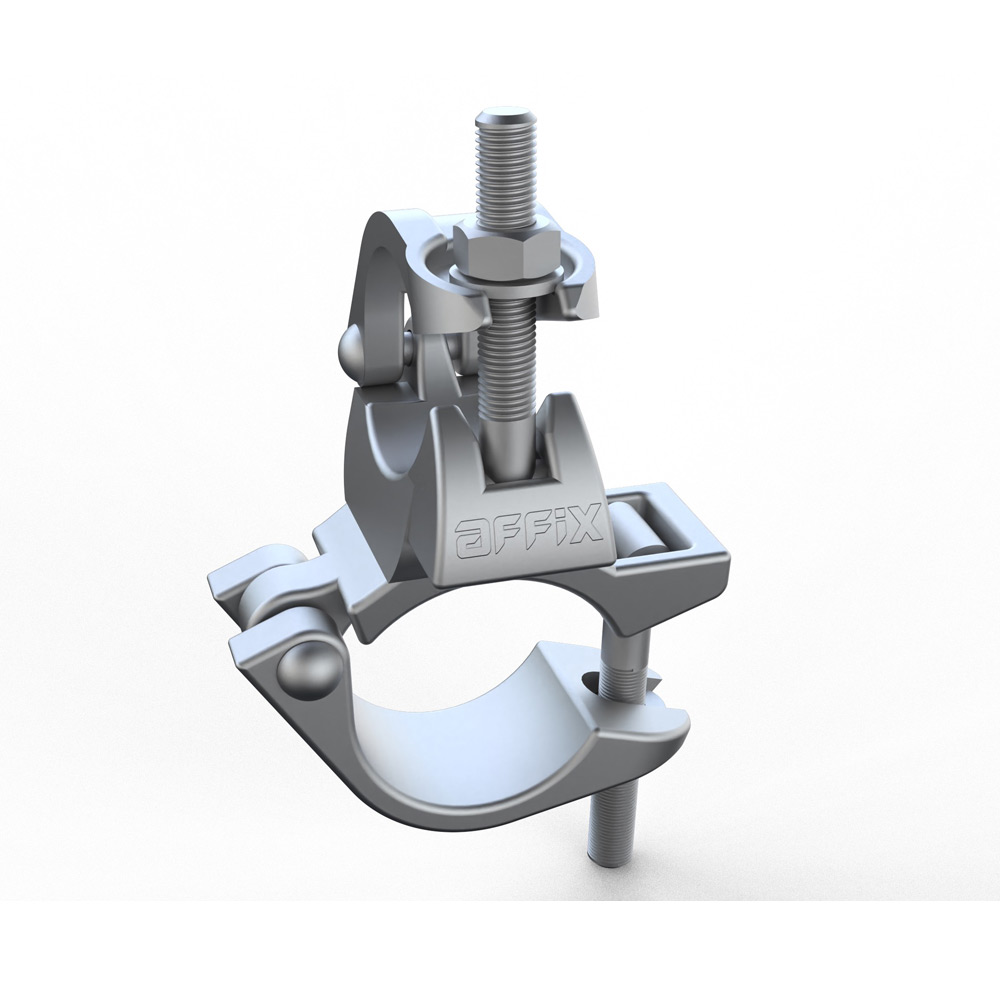

At its core, a double coupler is a forged or pressed steel fitting designed to grip two scaffold tubes securely at a 90-degree angle. Unlike swivel couplers, which offer rotational flexibility, the double coupler is all about rigidity. It’s used primarily in load-bearing nodes—areas where vertical standards meet horizontal ledgers—to ensure the framework remains stable under weight and wind pressure.

Its job is mechanical, but its impact is architectural. A well-designed and properly installed double coupler is what ensures a scaffold doesn’t lean under load, twist under torque, or give way under pressure.

Structural Integrity Begins With the Coupler

Every part of a scaffold relies on geometric stability. The verticals must stand upright. The horizontals must stay level. And the brace must resist both compression and tension. Without reliable fittings, even the most robust steel tubes can’t maintain their intended positions.

Double couplers are built for this exact purpose. Their ability to clamp tightly and distribute stress across the tubing connection makes them essential in preserving scaffold symmetry. This precise fitment reduces the risk of unintended flex or displacement, ensuring that every platform remains level and every load is transferred efficiently down through the standards to the base plates.

In large construction sites—like those seen in high-rise developments or major infrastructure projects in Saudi Arabia—precision in scaffold alignment directly translates into safety outcomes. It’s the double coupler that holds this alignment firm.

Load-Bearing Capacity: The Hidden Strength

While alignment and rigidity are the primary reasons for using double couplers, their strength is equally impressive. Engineered from high-grade forged steel or pressed steel, these couplers are built to withstand immense loads and resist shearing forces.

In scaffold design, moments of connection between horizontal and vertical tubes become critical load points. This is where stress from platforms, stored materials, and personnel converges. Double couplers manage these loads with minimal deformation. Their firm grip prevents sliding or separation, ensuring consistent support across the entire frame.

Even under dynamic loading—such as when workers shift, move tools, or operate equipment—double couplers maintain the scaffold’s composure. Their design minimizes micro-movements that can eventually lead to wear or misalignment.

Installation Accuracy with Double Couplers

Fastening a double coupler isn’t just about clamping tubes together; it’s about achieving exact angles and torque. Professional installers recognize that even slight deviations can lead to noticeable misalignments several meters up the scaffold. That’s why double couplers are preferred when precision matters.

Their uniform design allows site workers to standardize their connection points. Whether assembling modular scaffolds or customizing builds for irregular façades, workers can replicate right angles with consistency across multiple tiers and bays.

This repeatability also supports project efficiency. With double couplers, site managers can reduce guesswork and rework. The result is faster erection times, improved scaffold consistency, and reduced risk during inspections.

The Foundation of Safe Work Platforms

Walkways, working decks, and loading bays demand absolute trust from those who use them. A builder shouldn’t have to second-guess the stability of the platform underfoot. Double couplers contribute to this assurance by securing the key structural elements beneath each plank or working level.

Because they prevent lateral movement and twisting, double couplers help maintain level surfaces. They also reduce sagging across the span of ledgers, preserving the structural symmetry that scaffolding inspectors look for during safety checks.

Additionally, their corrosion resistance (when properly treated or galvanized) means they maintain clamping force even in harsh site conditions, including coastal or desert regions.

Engineered to Withstand Harsh Environments

Saudi Arabia’s climate puts construction equipment to the test. From the high heat of desert afternoons to potential dust storms or saline exposure near the coast, scaffolding components must be built to endure.

Double couplers, particularly those manufactured to international standards, are finished with galvanization or powder coating to resist rust and environmental degradation. These finishes not only protect the metal but ensure that gripping force isn’t compromised by corrosion or residue buildup.

On sites where sand abrasion or chemical exposure is frequent, high-grade couplers prove their worth. Their strength isn’t just about tonnage—it’s about consistency over time. A scaffold erected for six weeks must remain as secure on day 42 as it was on day 1. Double couplers help guarantee that.

Interchangeability and Versatility in System Builds

One of the reasons double couplers are widely used is their adaptability. Regardless of scaffold tube brand or length, the double coupler’s standard size makes it compatible across systems. This interchangeability allows contractors to expand or modify structures mid-project without sourcing proprietary parts or custom fittings.

In fast-paced environments where deadlines are tight and flexibility is key, this feature can save both time and capital. Whether adding guardrails, expanding platforms, or adjusting bracing, the double coupler fits the job.

Rigorous Compliance with International Standards

High-quality double couplers are manufactured to meet strict international standards such as BS1139, EN74, or equivalent. These standards dictate load-bearing capacity, dimensional tolerances, and material quality. Meeting these requirements ensures that each coupler performs as expected, even under unpredictable field conditions.

On major job sites—especially in regulated environments like petrochemical plants, airports, or urban infrastructure—compliance isn’t negotiable. Engineers and inspectors trust double couplers not only because of their form and function, but because they’ve been tested, certified, and proven.

This certification gives clients, foremen, and laborers peace of mind, knowing that their safety is being upheld by reliable components installed throughout the structure.

Reducing Human Error through Reliable Design

Even the most experienced scaffolders can make mistakes. A component that’s difficult to install, prone to slippage, or overly complex can increase the risk of failure. Double couplers eliminate much of this variability through intuitive, straightforward design.

By maintaining a consistent torque setting and providing predictable clamping force, they reduce the chances of under-tightening or over-stressing the scaffold tubes. Workers can rely on tactile and visual cues to confirm proper installation. This built-in simplicity helps prevent the kind of oversight that might otherwise lead to misalignments or weak points.

When safety is non-negotiable, this kind of reliability becomes priceless.

Cost-Efficiency Over the Lifecycle

Choosing quality double couplers may come with a higher initial investment, but their long-term value is undeniable. Inferior couplers often fail due to wear, corrosion, or compromised threading. Replacing these fittings during a project can disrupt schedules, increase labor costs, and jeopardize safety.

Premium double couplers resist degradation over the years of use. Their extended lifespan, reduced maintenance needs, and reliability under repeated stress cycles translate to lower operational costs over time. In industries where budgets and deadlines are tight, durable couplers make a significant difference.

Why Choose Affix Gulf Scaffolding Manufacturing LLC?

Affix Gulf Scaffolding Manufacturing LLC delivers precision-built scaffold components engineered for safety, performance, and longevity. Our double couplers are crafted to exceed expectations across demanding project sites and tested rigorously to align with global standards.

Contractors, builders, and industrial leaders trust Affix Gulf Scaffolding Manufacturing LLC because we prioritize detail in every product. Our double couplers are not just fittings—they’re part of the backbone of every safe, precise, and reliable scaffold structure.

Whether you’re building in the heat of Riyadh, along the coast in Jeddah, or on a major infrastructure site in Dammam, our couplers deliver the alignment you need with the quality you expect. When the stakes are high and the build must be exact, choose scaffold fittings designed with purpose—choose Affix Gulf Scaffolding Manufacturing LLC.